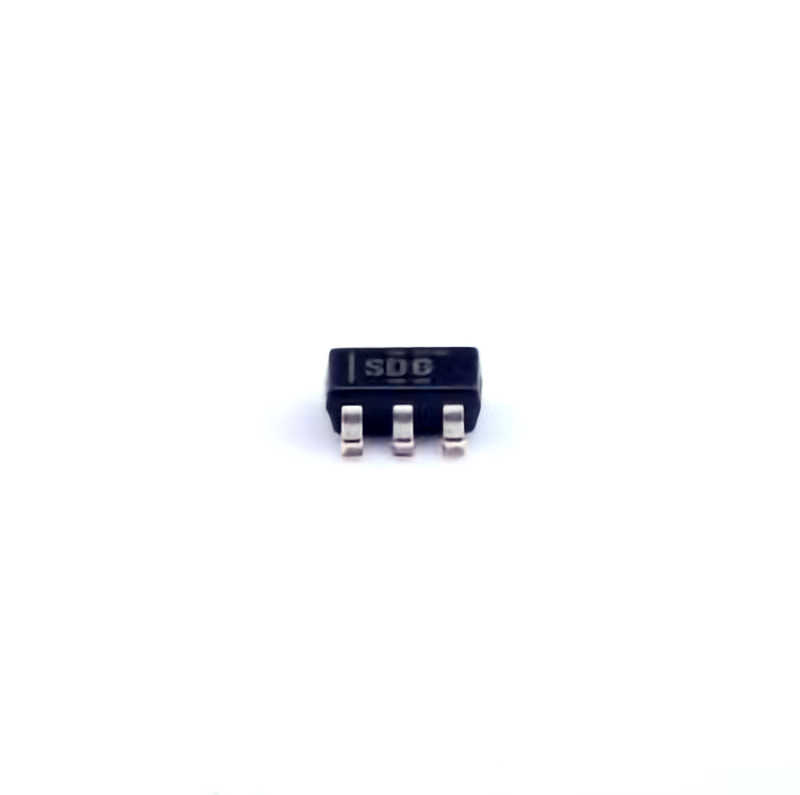

Understanding the TPS70933DBVR and Identifying Common Issues

The TPS70933DBVR is a low-dropout voltage regulator (LDO) that plays a critical role in providing stable voltage regulation in electronic systems. Known for its low dropout voltage, high efficiency, and compact package, the TPS70933DBVR is widely used in powering sensitive components, ensuring that voltage fluctuations or noise do not affect system pe RF ormance. However, like all electronics, issues can arise during integration, design, or field usage. Understanding these common problems and how to solve them is essential for engineers working with this component.

1. Output Voltage Instability

One of the most common problems faced by users of the TPS70933DBVR is instability in the output voltage. This issue can manifest as ripple, noise, or voltage fluctuations. The primary causes of output instability can be traced back to several factors:

Insufficient Input capacitor : The TPS70933DBVR requires a stable input voltage for proper operation. If the input capacitor is too small or not placed correctly, this can lead to noise and ripple on the output. Capacitors help filter out high-frequency noise and maintain a steady input voltage to the LDO.

Incorrect Output Capacitor: The LDO also depends on the correct type and value of an output capacitor to maintain stability. If the output capacitor is missing, of an incorrect value, or has poor quality (e.g., high ESR or low capacitance), the regulator may become unstable, causing excessive voltage fluctuations.

Load Transients: A sudden change in the load current can also cause the output voltage to dip or oscillate. The TPS70933DBVR, like many LDOs, requires careful design of the circuit to ensure stable performance during load changes.

Solution

To address output voltage instability:

Ensure that the input capacitor meets the recommended specifications (typically a low-ESR ceramic capacitor with a value of 10μF or higher).

Verify that the output capacitor is also appropriate for the LDO (typically a low-ESR ceramic capacitor of 1μF or higher is recommended).

Consider adding a compensation network if the design involves large load transients or sensitive circuitry.

2. Overheating of the LDO

Thermal issues are another common problem when using the TPS70933DBVR. The regulator can overheat if there is excessive power dissipation due to high input-to-output voltage differences or heavy load currents. Overheating can lead to thermal shutdown, reduced lifespan, or complete failure of the device.

High Dropout Voltage: The TPS70933DBVR has a low dropout voltage, but under certain conditions—such as when the input voltage is only slightly higher than the output voltage—the LDO may dissipate more heat than expected.

Excessive Load Current: If the output current exceeds the rated capability of the device (3A for the TPS70933DBVR), it can cause excessive heating and thermal shutdown.

Inadequate Heat Sinking: In applications with higher power dissipation, not providing adequate heat sinking or PCB design to dissipate heat can lead to thermal problems.

Solution

To prevent overheating:

Ensure the input-to-output voltage difference is as small as possible. If a higher voltage drop is required, consider using a switching regulator (buck converter) instead of an LDO.

Always stay within the recommended current limits. The TPS70933DBVR is rated for 3A, but running near the maximum limit continuously can lead to heating issues.

Improve heat dissipation by using larger copper areas on the PCB or adding external heatsinks if necessary.

3. Output Voltage Too High or Too Low

Another frequent issue with the TPS70933DBVR is when the output voltage is either too high or too low, compared to the expected value. This can occur due to various reasons related to the design or external factors affecting the regulator’s performance.

Incorrect Resistor Divider: The TPS70933DBVR can be configured for different output voltages through an external resistor divider. If these resistors are of incorrect values or poorly matched, the output voltage will deviate from the expected value.

Faulty Feedback Loop: The feedback loop that regulates the output voltage is sensitive to noise and impedance mismatches. If there is any instability in the feedback network or an improper connection, the output voltage can be incorrect.

Solution

Double-check the values of the resistors used in the feedback divider for accuracy.

Ensure that the feedback path is short, well-routed, and shielded from noise or interference that could disrupt the regulation.

4. No Output Voltage (Complete Failure)

A complete failure of the TPS70933DBVR can result in no output voltage, which can be due to several factors:

Faulty or Missing Ground Connection: Ensure that the ground pin is connected properly, as a broken or missing ground connection can prevent the regulator from operating.

Input Voltage Below Dropout: The TPS70933DBVR requires the input voltage to be higher than the output voltage by at least the dropout voltage. If the input voltage is too low, the regulator will not output the expected voltage.

Short Circuit: A short circuit on the output or a defective component connected to the LDO can cause it to shut down or fail to provide the correct output voltage.

Solution

Check for a proper ground connection and ensure that the input voltage is sufficiently above the output voltage (by at least the dropout voltage).

Check for any shorts or damaged components that might cause the regulator to fail.

Advanced Troubleshooting Tips and Solutions for the TPS70933DBVR

While basic troubleshooting can often resolve common issues with the TPS70933DBVR, more advanced techniques are sometimes necessary for resolving tricky problems. In this section, we'll explore some of the deeper troubleshooting methods and design considerations that can help you get the best performance out of your LDO.

1. Noise and Ripple Suppression

When working with sensitive analog or digital circuits, noise and ripple on the output voltage can be detrimental to system performance. The TPS70933DBVR is designed with low noise in mind, but it still requires proper PCB layout and external components to maintain clean output.

PCB Layout: Ensure that the ground plane is continuous and low impedance, and avoid running noisy traces near the LDO’s feedback pin or ground pin.

Bypass Capacitors: Place high-quality ceramic capacitors (such as 0.1µF or 10µF) as close as possible to the input and output pins of the LDO to minimize ripple and noise.

Shielding: In some cases, electromagnetic interference ( EMI ) from nearby components may cause noise on the LDO output. In such cases, shielding or ferrite beads may help.

Solution

Pay attention to PCB layout and grounding techniques. Use the shortest possible traces for the input, output, and feedback pins.

Add low ESR ceramic capacitors at both the input and output to filter out high-frequency noise.

Consider using additional filtering elements like ferrite beads or low-pass filters if noise levels remain high.

2. Load Regulation and Transient Response

While the TPS70933DBVR provides stable output voltage under steady load conditions, transient responses to sudden changes in the load current can cause temporary voltage dips or overshoot. This is a particular concern in precision applications like RF or audio circuits, where even small voltage fluctuations can cause performance issues.

Load Transients: Sudden changes in load current can create voltage dips or overshoot, especially if the feedback loop is not adequately compensated.

Compensation Networks: If you’re experiencing poor transient response or slow recovery times, consider adding external compensation to improve the LDO’s transient performance.

Solution

Ensure that the power supply and decoupling capacitors are of sufficient value to handle sudden load changes.

Use compensation techniques such as adding a series resistor or capacitor to the feedback loop to improve transient response.

3. Thermal Management and Extended Life

For long-term reliability, it is crucial to manage the thermal performance of the TPS70933DBVR. Operating the device at higher temperatures can significantly reduce its lifespan and efficiency. Monitoring the thermal performance in real-time during operation can be an effective method for diagnosing overheating issues before they cause damage.

Solution

Implement good thermal management practices, such as increasing PCB copper area around the LDO, using heat sinks if necessary, and ensuring proper airflow.

Consider using temperature sensors or thermal monitoring ICs to keep track of the LDO's temperature and prevent overheating.

In conclusion, the TPS70933DBVR is a reliable and versatile LDO that can perform optimally when designed and implemented correctly. By following the troubleshooting tips outlined in this article, you can address common issues such as output instability, overheating, and voltage discrepancies. Proper design, component selection, and thermal management are key to maximizing the performance and longevity of the TPS70933DBVR.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.