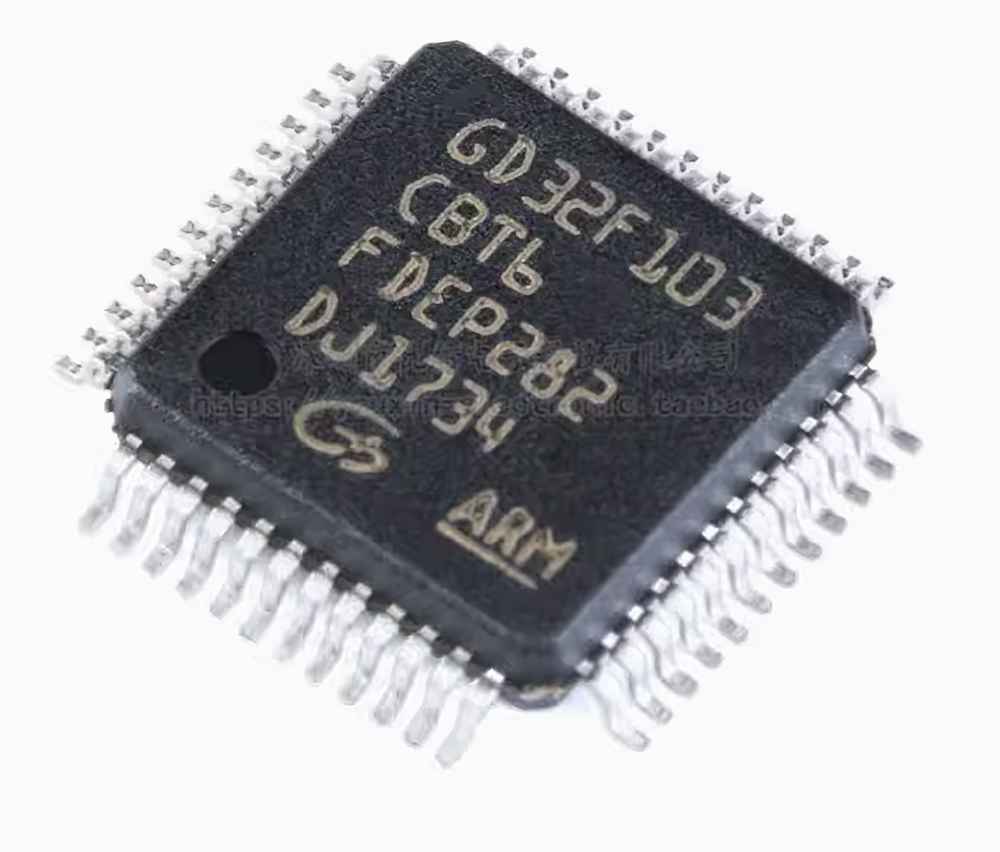

Common Troubleshooting Issues with GD32F103CBT6

The GD32F103CBT6 is a widely-used ARM Cortex-M3 microcontroller in embedded systems, offering excellent performance and a range of features suitable for industrial, consumer, and Communication applications. However, like all hardware components, it can encounter issues during development, which can hinder progress. Engineers need to understand common problems and their solutions to ensure smooth operation.

Here’s a deep dive into some frequent issues and troubleshooting techniques for GD32F103CBT6 microcontrollers:

1. Power Supply Issues

One of the most common causes of malfunctioning GD32F103CBT6 microcontrollers is an improper power supply. A weak or unstable power source can cause the chip to reset unexpectedly or fail to initialize.

Solution:

Ensure the power supply is stable and within the microcontroller’s rated voltage range, typically 2.6V to 3.6V. Check the power source using a multimeter to confirm that the voltage levels are consistent. Additionally, verify that there are no significant voltage drops when the microcontroller is in operation. Use capacitor s for decoupling near the power pins to reduce noise and voltage fluctuations. A good practice is to use at least a 10uF ceramic capacitor between VCC and GND to filter out high-frequency noise.

2. Incorrect Clock Configuration

The GD32F103CBT6 microcontroller relies on an external crystal oscillator (HSE) or internal oscillator (HSI) to provide the clock signal. If the clock configuration is incorrect, the system can either fail to start or run at an incorrect frequency, leading to erratic behavior or failures in timing-dependent tasks.

Solution:

Check the configuration of the clock settings in the microcontroller's startup code. The STM32CubeMX tool can assist in generating correct clock tree configurations. Also, double-check the external crystal or resonator's specifications (if used). Ensure that the correct clock source is selected and that the startup code configures the PLL (Phase-Locked Loop) or the system clock properly. If using HSE, make sure the crystal is properly connected, and check the load capacitance for accuracy.

3. Firmware and Bootloader Problems

Firmware or bootloader issues can prevent the GD32F103CBT6 from properly initializing or cause it to enter a fault state where no functionality is available.

Solution:

Ensure that the bootloader and firmware are correctly loaded onto the device. You can use a debugger such as ST-Link or J-Link to flash the firmware again or step through the code to pinpoint where the failure occurs. If the device enters the bootloader but fails to communicate with external peripherals, verify the boot mode settings by checking the status of the BOOT0 pin. In some cases, a corrupt bootloader might prevent the microcontroller from booting into the application mode. Reflashing the firmware via a JTAG/SWD interface can often solve this problem.

4. Debugging Communication Failures

Many embedded systems rely on UART, SPI, or I2C for communication with peripherals, and troubleshooting communication failures can be tricky. The GD32F103CBT6 has several dedicated pins for different communication protocols, and pin misconfigurations are a common cause of communication issues.

Solution:

Double-check the configuration of the GPIO pins and ensure that they match the pinout of the communication protocol being used. Using an oscilloscope or logic analyzer to monitor the signals on the communication lines (TX, RX, SCL, SDA, etc.) can help identify whether the signals are being transmitted correctly. Make sure that the baud rate and clock speed for UART, SPI, or I2C are set correctly in both the microcontroller and the external devices.

5. Peripheral Misconfiguration

Many developers encounter problems when setting up peripherals, such as timers, ADCs, or PWM. The GD32F103CBT6 offers a wide range of peripherals, but incorrect initialization or conflicts can cause them to malfunction.

Solution:

Consult the datasheet and reference manual to verify the correct configuration of the peripheral in question. For example, if you're working with timers, make sure the prescaler, auto-reload values, and clock sources are properly set. If you're using ADCs or DACs, check the alignment of the data, sampling times, and trigger sources. For peripherals like PWM, ensure that the duty cycle and frequency are correctly calculated based on the system clock.

Use the HAL (Hardware Abstraction Layer) libraries or low-level drivers to simplify peripheral initialization. These libraries often contain built-in error checks and configuration examples that can help resolve peripheral issues.

6. Overheating or Inadequate Cooling

When running at high clock speeds or under heavy load, the GD32F103CBT6 can overheat if proper cooling measures are not implemented. Overheating can cause unpredictable behavior, ranging from crashes to total device failure.

Solution:

Ensure the microcontroller has adequate heat dissipation. While the GD32F103CBT6 doesn’t typically require a heatsink for most applications, it’s still essential to monitor the temperature. Use a temperature sensor or a thermal camera to check if the chip gets too hot under heavy loads. If necessary, add passive cooling solutions like heat sinks or ensure the microcontroller is in a well-ventilated enclosure.

7. Booting from External Flash or Memory

Sometimes, users may encounter problems when attempting to boot the GD32F103CBT6 from external memory, such as an SPI Flash. This can occur if the configuration of the memory interface is incorrect or if the external memory is not properly initialized.

Solution:

Check the configuration of the memory interface (SPI or parallel) and ensure the read/write operations are properly set up. Verify that the external memory is correctly powered and that all connections are secure. When booting from external memory, ensure that the system is set to use the correct bootloader. If possible, connect the microcontroller to a debugger to step through the boot process and verify the execution path.

Advanced Troubleshooting and Preventative Measures for GD32F103CBT6

After addressing the basic troubleshooting steps above, it’s crucial to understand more advanced diagnostics techniques and preventive measures that can save time in future projects.

8. Static Electricity Damage

Static discharge is one of the silent killers of microcontrollers. Sensitive components like the GD32F103CBT6 can be permanently damaged by electrostatic discharge (ESD), leading to erratic behavior, corruption, or outright failure.

Solution:

Always handle the microcontroller and associated components in ESD-safe environments. Use an ESD mat, wrist strap, and grounded tools to prevent static buildup. Store the microcontroller in anti-static bags when not in use. If your development environment lacks proper ESD protection, you risk irreparably damaging sensitive components during testing, assembly, or even routine handling.

9. Software Debugging with JTAG and SWD

Software bugs can sometimes be difficult to diagnose because they don’t manifest as clear hardware failures. JTAG (Joint Test Action Group) and SWD (Serial Wire Debug) are invaluable tools for advanced software debugging.

Solution:

Use a JTAG or SWD debugger to step through your code and identify logical errors, memory corruption, or unintended program flow. Debuggers allow you to halt the processor, inspect registers, and step through the code line by line. Tools like OpenOCD, Segger J-Link, and ST-Link offer support for JTAG and SWD protocols, providing visibility into the internal state of the microcontroller.

Additionally, utilizing a logic analyzer or oscilloscope in combination with the debugger can provide a real-time view of system interactions, helping you correlate software and hardware behavior.

10. Memory Leaks and Buffer Overflows

Memory management issues, such as memory leaks or buffer overflows, can cause unpredictable behavior and system crashes. The GD32F103CBT6 microcontroller has limited SRAM and flash memory, and improper memory management can lead to performance degradation or crashes.

Solution:

Use static code analysis tools to detect potential memory management issues. Tools like Lint, or integrated development environments (IDEs) like STM32CubeIDE, offer memory usage tracking and warnings for buffer overflows. When working with dynamic memory allocation, always check for successful allocation and deallocate unused memory properly. Keep an eye on the stack size to avoid stack overflows.

11. Firmware Update and Version Control

Firmware updates are crucial for fixing bugs, adding new features, or enhancing security. However, improper updates or version conflicts can create new problems.

Solution:

Use version control systems like Git to track changes to your firmware. Always maintain backups of stable versions and ensure that your update process is well-documented. Consider implementing a safe firmware update mechanism that ensures the microcontroller can revert to a previous version in case of a failed update.

12. Using Watchdogs to Prevent System Locks

In embedded systems, it's essential to have a watchdog timer that resets the system in case of a software or hardware failure. The GD32F103CBT6 includes a watchdog timer that can be configured to ensure the microcontroller doesn’t get stuck in an infinite loop or enter an error state.

Solution:

Enable the Independent Watchdog (IWDG) or the Window Watchdog (WWDG) in your application. The watchdog can be periodically reset by the software, and if the software fails to reset the watchdog within a specified period, the microcontroller will reset, ensuring that the system doesn’t freeze.

Conclusion

The GD32F103CBT6 microcontroller is a versatile and reliable option for embedded systems development. However, like all electronic devices, it can face issues ranging from simple power supply problems to more complex firmware bugs or peripheral misconfigurations. By understanding common troubleshooting techniques and implementing proactive measures, engineers can quickly identify and resolve issues, ensuring smooth operation and improved reliability in their embedded systems. With the proper tools, methods, and preventive practices, developers can minimize downtime and enhance the efficiency of their designs.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.