Introduction to RS485 and the SP3485 transceiver

In the world of industrial automation, reliable Communication is the cornerstone of efficient operations. Whether in factory environments, control systems, or automated machinery, maintaining fast, secure, and uninterrupted communication between different devices is crucial. One of the most widely used communication protocols in industrial environments is RS485. RS485 offers robust data transmission over long distances, making it ideal for harsh and noisy industrial settings. Within this context, the SP3485 RS485 transceiver stands out as a reliable and efficient solution for ensuring high-performance communication in industrial automation systems.

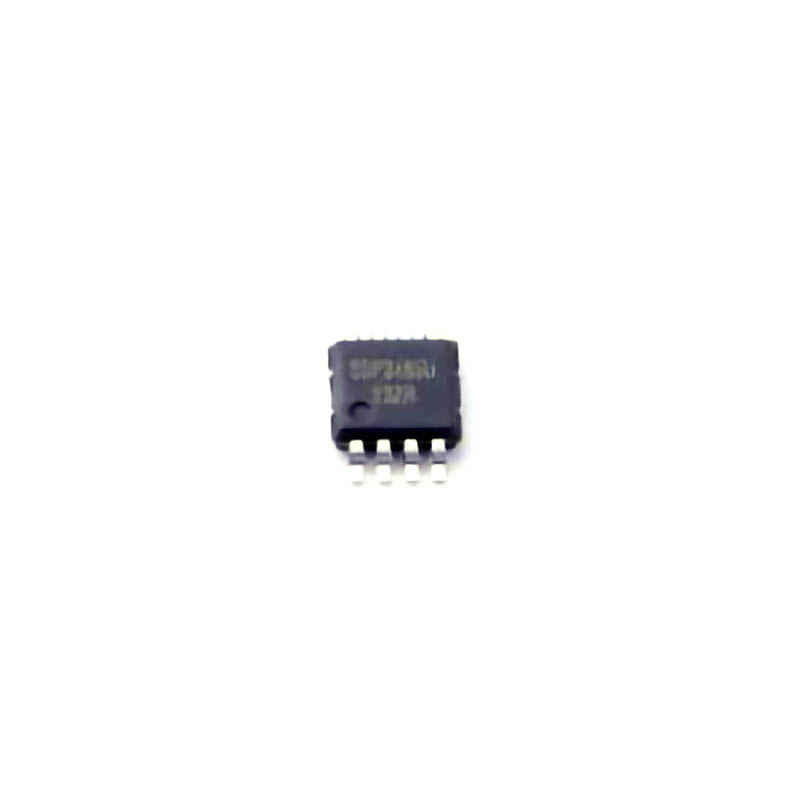

The SP3485 is a low- Power , half-duplex transceiver designed specifically to work with the RS485 communication protocol. The transceiver enables bidirectional data transmission over a twisted pair of wires, providing reliable communication even in electrically noisy environments. Its low power consumption, high-speed performance, and robust design make it an excellent choice for industrial applications where reliability and signal integrity are essential.

Features of the SP3485 RS485 Transceiver

Before diving into its applications, it's important to understand the core features of the SP3485 that make it an ideal choice for industrial automation:

Low Power Consumption: The SP3485 is designed to operate at low power, making it perfect for systems where energy efficiency is crucial.

High-Speed Communication: The transceiver supports data rates of up to 10 Mbps, ensuring fast communication in real-time industrial systems.

Wide Operating Voltage Range: With a voltage range of 3.3V to 5.5V, the SP3485 can be used in a variety of devices with differing voltage requirements.

Improved Noise Immunity: Thanks to the differential signaling of the RS485 protocol, the SP3485 can operate in environments with high electromagnetic interference ( EMI ), a common problem in industrial settings.

Multi-Device Communication: RS485 allows multiple devices to be connected on the same bus, enabling seamless communication across large and distributed automation systems.

These features make the SP3485 RS485 transceiver an essential component in industrial automation networks that demand high reliability, low latency, and resistance to environmental noise.

The Role of RS485 in Industrial Automation

RS485 is an industry-standard protocol for long-distance, differential signal communication, widely used in industrial automation systems. It is particularly effective in environments where electromagnetic interference (EMI) could disrupt simpler communication methods like RS232. The ability of RS485 to transmit data over long distances (up to 4000 feet) with multiple devices connected to the same bus makes it ideal for factory floors, automated assembly lines, process control systems, and remote sensor networks.

RS485’s differential signaling also ensures that the data transmission is less affected by electrical noise, a common challenge in industrial environments. The SP3485 transceiver takes full advantage of these features, providing a cost-effective and efficient solution to overcome communication barriers in complex industrial automation setups.

Application Example: Automated Manufacturing Systems

A common application of the SP3485 RS485 transceiver is in automated manufacturing systems. In such systems, various machines, sensors, and Controllers must communicate in real-time to ensure optimal operation. This communication includes sending data on machine performance, triggering alarms, adjusting settings, and updating control parameters across different parts of the production line.

Let’s consider an example of a manufacturing plant where multiple automated machines need to work in sync to produce a product. These machines are connected through a central control unit, which collects data and sends commands. The use of RS485 communication allows the control unit to interface with multiple machines at once, sending commands or receiving feedback from sensors, actuators, or PLCs (Programmable Logic Controllers ).

In this scenario, the SP3485 transceiver provides reliable data transmission across the RS485 bus, enabling real-time monitoring and control of each machine. Due to the noise-resilience of RS485, communication is stable even in environments with high electrical interference, such as around motors, large machines, or welding equipment.

Ensuring Robust Communication in Harsh Environments

One of the major challenges in industrial automation is ensuring reliable communication in harsh environments. Factories often feature high levels of electromagnetic interference (EMI), which can degrade the performance of standard communication protocols. The SP3485 transceiver addresses this challenge by utilizing differential signaling, which is less susceptible to noise compared to single-ended signals. This makes the SP3485 particularly effective in settings like manufacturing floors, power plants, and warehouses, where EMI can be problematic.

Additionally, the SP3485’s wide operating voltage range ensures compatibility with a wide variety of industrial equipment, further simplifying integration across different subsystems. Whether it’s controlling HVAC systems, monitoring pressure levels, or tracking production statistics, the SP3485 helps maintain stable communication, even when there are fluctuations in voltage or electrical noise in the environment.

Integrating SP3485 RS485 Transceivers into Industrial Networks

Industrial automation systems often consist of complex, multi-tiered networks with many devices that need to communicate with each other. This includes sensors, actuators, PLC controllers, data loggers, and human-machine interfaces (HMIs). Integrating the SP3485 RS485 transceiver into these networks allows for seamless data transfer between all devices on the network.

For instance, in a process control system used in a chemical plant, several devices need to communicate continuously to monitor parameters like temperature, pressure, and flow rate. The SP3485 transceiver can facilitate the connection between these devices, ensuring data is transmitted accurately over long distances. The transceiver's ability to support multiple devices on the same bus means that dozens of sensors can send data to the central control system without requiring separate communication lines for each device.

This versatility makes the SP3485 an ideal choice for large-scale industrial networks, where the demand for reliable, multi-device communication is high. The integration of SP3485-based transceivers allows companies to streamline operations and reduce the complexity of their communication networks, ultimately improving the efficiency and maintainability of their automation systems.

Cost-Effectiveness and Long-Term Benefits

The adoption of RS485 transceivers like the SP3485 not only enhances communication reliability but also provides long-term cost-saving benefits. While it’s essential to invest in quality communication hardware for industrial automation, the SP3485’s low power consumption and durability ensure it’s an economical choice for both small and large-scale applications.

Furthermore, the robustness of RS485 communication reduces the need for frequent maintenance or troubleshooting, as it is less prone to issues caused by external electrical noise, cable degradation, or voltage spikes. The ability to run communication over long distances without signal loss also reduces the need for costly repeaters or additional infrastructure.

In the long term, the SP3485 enables companies to build future-proof automation systems. As automation continues to evolve and become more complex, having a reliable, scalable communication protocol like RS485 becomes increasingly important. The SP3485 transceiver ensures that systems remain compatible with future upgrades, as it is widely used and supported across the industrial automation industry.

Conclusion: Unlocking the Full Potential of Industrial Automation

The integration of the SP3485 RS485 transceiver into industrial automation systems offers a powerful solution for achieving high-speed, reliable, and cost-effective communication. Whether used in automated manufacturing, process control, or remote sensing applications, the SP3485 ensures that data flows seamlessly across devices, even in the most challenging industrial environments.

With its low power consumption, resistance to noise, and compatibility with a wide range of industrial devices, the SP3485 is a versatile and indispensable tool for modern automation networks. By leveraging the capabilities of the SP3485, companies can enhance operational efficiency, reduce downtime, and future-proof their automation infrastructure for the years to come.

In a world where industrial automation is becoming more intricate, maintaining a robust communication backbone is essential. The SP3485 RS485 transceiver is at the heart of that backbone, ensuring smooth, continuous, and reliable operations across a vast array of industrial applications.

This structure provides an engaging, informative, and easy-to-understand article suitable for audiences interested in learning about the SP3485 RS485 transceiver’s role in industrial automation, with a clear focus on its benefits and applications.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.