Common Troubleshooting Scenarios for the MAX13085EESA

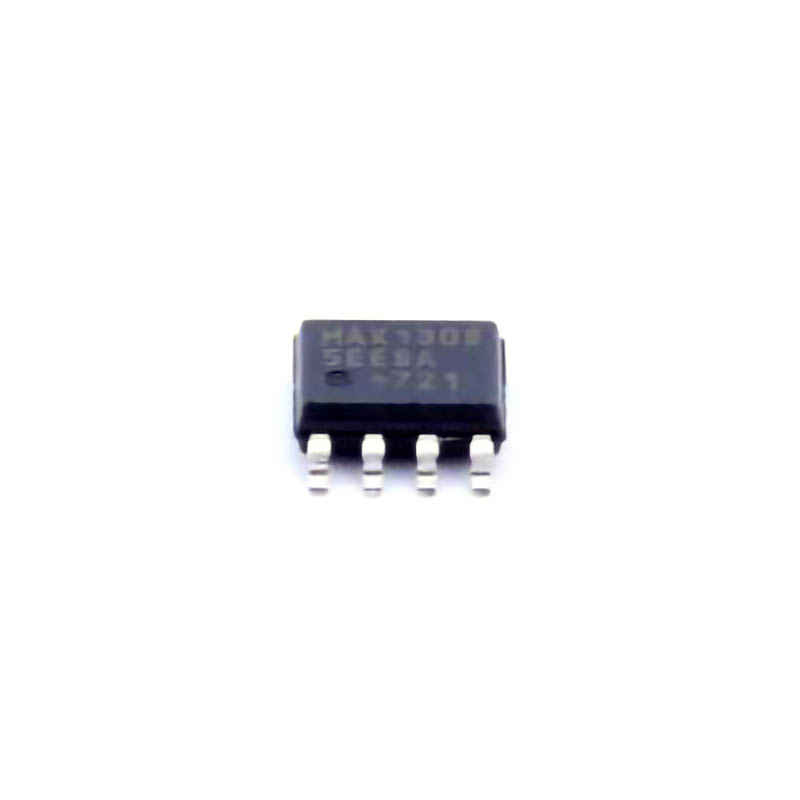

The ADI MAX13085EESA is a Power ful RS-485 transceiver designed to provide reliable Communication over long distances in industrial and commercial environments. However, like any electronic device, issues can arise during its operation. This part of the article will focus on common troubleshooting problems that users may face when working with the MAX13085EESA.

1. No Communication or Loss of Signal

One of the most common issues with the MAX13085EESA is the complete loss of communication. This can manifest in various ways, such as no data transmission, sporadic data transfers, or complete failure to establish communication.

Potential Causes:

Incorrect Wiring: The MAX13085EESA requires careful attention to wiring. RS-485 communication is differential, and improper connections can result in signal degradation or complete loss of communication. Ensure that the A and B lines are correctly connected and that there are no short circuits between them.

Bus Termination Issues: RS-485 networks require proper termination to prevent signal reflections. Without termination Resistors at the ends of the bus, the signal integrity could degrade, leading to communication failure.

Power Supply Problems: Insufficient or unstable power supply voltage can lead to the malfunctioning of the transceiver. Check the supply voltage levels to ensure that the MAX13085EESA is receiving a stable voltage (typically 3.3V or 5V) as required for optimal operation.

Faulty Transceiver: A damaged or defective MAX13085EESA can also be the source of the problem. If all other troubleshooting steps fail, testing the transceiver in isolation or replacing it may be necessary.

Solution:

Double-check all wiring and connections to ensure correct polarity and no shorts.

Verify that appropriate termination resistors (typically 120Ω) are placed at both ends of the bus.

Use a multimeter or oscilloscope to measure the power supply voltage and ensure it is within the recommended range.

Test the transceiver on a different circuit or replace it with a known working device to confirm its functionality.

2. Poor Signal Integrity and Noise Issues

Signal degradation due to electromagnetic interference ( EMI ) or improper design of the bus network can cause poor signal integrity, leading to data errors or unreliable communication.

Potential Causes:

Long Cable Runs: RS-485 is designed for long-distance communication, but excessively long cable runs can introduce noise and weaken the signal. This is especially problematic when the signal is transmitted at high baud rates.

Improper Grounding: Poor grounding of the circuit can increase the susceptibility of the system to noise, affecting the integrity of the transmitted data.

Impedance Mismatch: When the impedance of the cable or the termination resistor does not match the impedance of the transceiver, signal reflections can occur, which will distort the signal and cause communication issues.

Solution:

Use shorter cable lengths where possible and ensure that the cables used are designed for RS-485 communication (e.g., twisted-pair cables).

Make sure the system is properly grounded. Grounding should be done at a single point to avoid ground loops, which can introduce noise into the system.

Implement the correct termination impedance, typically 120Ω, and ensure that the cables used match the system’s impedance specifications.

3. Incorrect Baud Rate or Data Format

Another common issue in RS-485 communication systems involves mismatched baud rates or incorrect data formats. The MAX13085EESA transceiver communicates using standard RS-485 protocols, but for successful communication, all devices in the network must be synchronized in terms of baud rate, parity, and data frame format.

Potential Causes:

Mismatched Baud Rate: If one device operates at a higher or lower baud rate than others, communication errors will occur. The baud rate must be the same for all devices in the network.

Incorrect Parity or Stop Bits: Parity settings and the number of stop bits should also match across all devices. Any deviation from a consistent data frame format will result in corruption or misinterpretation of data.

Solution:

Ensure that all devices on the RS-485 bus are configured with the same baud rate. Check the baud rate settings in the communication software or firmware.

Verify the data frame configuration (parity, stop bits, data bits) for all devices on the network. They must match exactly to ensure proper communication.

4. Driver and Receiver Failures

The MAX13085EESA operates as both a transmitter and a receiver, meaning that both sides of the transceiver need to be functioning correctly. If either the driver or the receiver is malfunctioning, communication may be disrupted.

Potential Causes:

Overloading the Bus: If too many devices are connected to the bus or if the transceiver is subjected to excessive loading, it can cause the driver or receiver to fail.

Faulty Driver Circuit: If the driver circuitry on the MAX13085EESA is faulty, it may not be able to send or receive signals properly.

Short Circuits on the Bus: A short circuit anywhere on the RS-485 bus, such as between the A and B lines, can prevent the MAX13085EESA from functioning correctly.

Solution:

Reduce the number of devices connected to the bus and ensure proper load conditions.

Test the transceiver’s driver and receiver circuits using diagnostic tools like oscilloscopes to confirm that both circuits are operating as expected.

Check for shorts in the wiring or bus connections and resolve any issues.

5. Overheating and Thermal Shutdown

If the MAX13085EESA is subjected to excessive heat, it may enter thermal shutdown to protect itself from damage. Overheating can be caused by inadequate cooling, excessive current draw, or prolonged operation at high power levels.

Potential Causes:

Excessive Current Consumption: The transceiver may draw more current than expected, especially under high-speed data transmission conditions, which can lead to overheating.

Inadequate Heat Dissipation: If the MAX13085EESA is enclosed in a case with poor ventilation or is placed near heat-generating components, it may overheat.

Power Supply Issues: An unstable or fluctuating power supply can cause the device to heat up due to power surges.

Solution:

Ensure that the MAX13085EESA is not exposed to excessive current. Use current-limiting resistors or proper current regulation to prevent overdraw.

Improve ventilation around the transceiver or use heat sinks to dissipate heat more efficiently.

Check the power supply to ensure that it is stable and within the specified range.

Advanced Troubleshooting and Preventive Solutions for MAX13085EESA

6. Bus Contention or Data Collision

RS-485 is a multi-point communication system, which means multiple devices can share the same bus. However, when two devices attempt to transmit at the same time, a data collision can occur, which results in corrupted data and loss of communication.

Potential Causes:

Simultaneous Transmission: If more than one device attempts to drive the bus at the same time, a collision will occur.

Improper Bus Arbitration: If the devices on the bus do not have proper bus arbitration mechanisms in place, it can lead to contention and collisions.

Solution:

Implement proper bus arbitration in the software or hardware of the system to ensure that only one device transmits at any given time.

Use a multi-master or half-duplex system with correct handshake protocols to avoid collisions.

7. Voltage Spikes and Transients

In industrial environments, voltage spikes and transients from nearby equipment or environmental factors (e.g., lightning strikes, motors, or switching relays) can damage the MAX13085EESA or disrupt its communication.

Potential Causes:

Inductive Loads: Devices such as motors and relays can generate voltage spikes when they are turned on or off.

Electromagnetic Interference (EMI): High-frequency signals from nearby equipment can induce voltage transients on the RS-485 bus.

Solution:

Use surge protection devices like transient voltage suppressors ( TVS ) or diodes to protect the transceiver from voltage spikes.

Install filters on the power lines and ensure proper shielding for the RS-485 communication cables to reduce the effects of EMI.

8. Incorrect Use of Termination Resistors

In an RS-485 network, incorrect termination of the bus can lead to reflections, signal distortion, and reduced communication range. Proper termination is crucial for maintaining signal quality, especially in long-distance applications.

Potential Causes:

Inadequate Termination: Failing to place termination resistors at both ends of the bus can lead to signal reflections and data errors.

Improper Termination Resistance : The termination resistance should match the characteristic impedance of the cable (usually 120Ω). Using the wrong value can affect signal integrity.

Solution:

Place 120Ω termination resistors at both ends of the RS-485 bus, and check that the resistance matches the cable’s impedance.

For networks longer than 10 meters, consider adding biasing resistors to ensure proper voltage levels on the A and B lines.

9. Firmware and Software Issues

Sometimes, issues with the MAX13085EESA may not be related to the hardware but rather to the firmware or software that drives the device. Incorrect configuration, bugs, or unoptimized code can all lead to communication failures.

Potential Causes:

Incorrect Register Configuration: The MAX13085EESA is configured through a set of registers. Incorrect settings for features such as driver enable or receive enable can cause problems.

Timing Issues in Software: Delays in sending or receiving data due to inefficient software can result in missed or corrupted data.

Solution:

Review and optimize the firmware to ensure that the registers controlling the MAX13085EESA are correctly set up for the desired communication mode.

Ensure that the software is free of bugs that could interfere with the timing or flow of data between the transceiver and the rest of the system.

10. Preventive Measures for Long-Term Reliability

To avoid common issues in the future and ensure long-term reliability, preventive measures should be taken during both the design and operational phases.

Solution:

Regularly check and calibrate the system to ensure that the power supply and data integrity are maintained.

Monitor the temperature and environmental conditions to avoid overheating or damage from external factors.

Conduct periodic inspections and testing using diagnostic tools like oscilloscopes or protocol analyzers to identify early signs of failure.

Conclusion

Troubleshooting the MAX13085EESA RS-485 transceiver requires a systematic approach to identifying and solving potential issues. By understanding common problems like signal degradation, wiring errors, and device malfunctions, and implementing appropriate solutions, engineers and technicians can ensure reliable and efficient performance of this crucial component in communication systems. Preventive measures, regular testing, and proper configuration can help avoid these problems in the future, ensuring that the MAX13085EESA continues to perform at its best in industrial and commercial applications.

If you’re looking for models of commonly used electronic components or more information about MAX13085EESA datasheets, compile all your procurement and CAD information in one place.

(Partnering with an electronic component supplier) sets your team up for success, ensuring that the design, production and procurement processes are streamlined and error-free. (Contact us) for free today